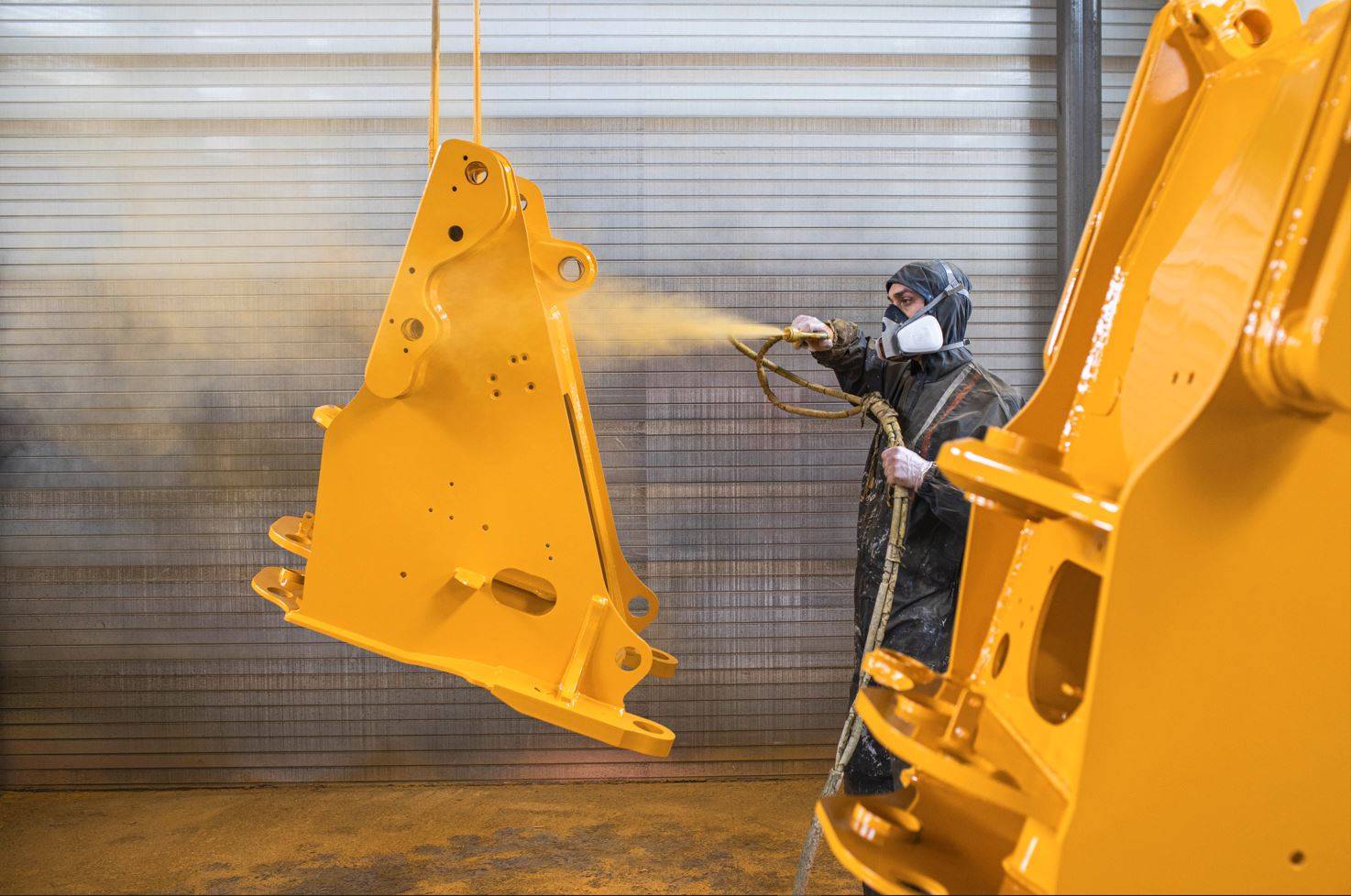

Tehnologija Farbanja

GS – TMT izvodi mehaničku pripremu površine za proces premazivanja i sačmarenja prema EN ISO 8501. Imamo protočnu sačmarnicu GOSTOL i sačmaricu GOSTOL.

GS-TMT nudi nekoliko vrsta

suvremenih površinskih obrada

– Pjeskarenje

– Mokro farbanje

– Sirova isporuka toplinski obrađenih elemenata

Kapaciteti površinske obrade

Blowtherm Model 1500

Grijanje Owen

Jedinica za pjeskarenje

Wagner jedinica za nanošenje premaza kapaciteta 4 metra

Peći za toplinsku obradu nakon zavarivanja

Postupak nanošenja organskih premaza (primer i završni premaz se radi prema EN ISO 12944). Premaz se nanosi AIR MIX uređajima (štrcaljke, pumpe) za mokro nanošenje. Proces premazivanja odvija se u dvodijelnim BLOWTERM komorama dimenzija 16,7x5x4 s kontroliranim radnim uvjetima (radna temperatura, temperatura sušenja, nosači, ventilacijski odvod).

Osposobljeni smo za mjerenje debljine premaza, mjerenje sjaja premaza, test prionjivosti, test kemijske postojanosti premaza kao i mjerenje ΔE, Δ4, Δa, Δb.

Izgradimo nešto zajedno

gs – tvornica mašina travnik

Od 1952.